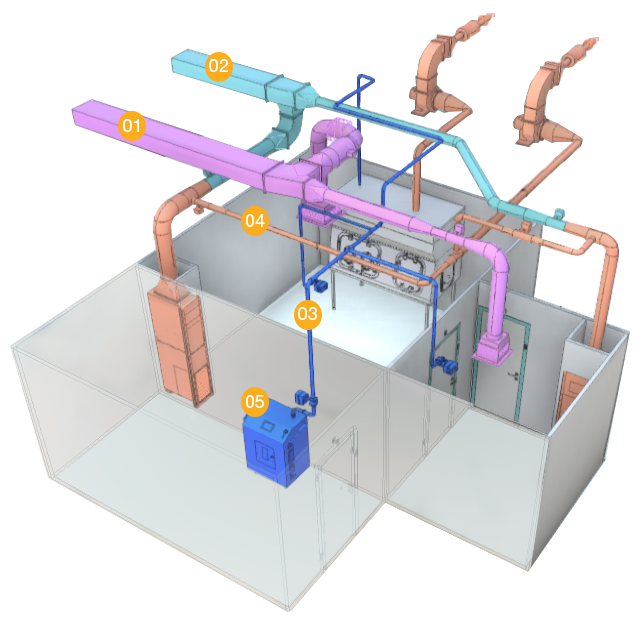

Decontamination of rooms and equipment using a hydrogen peroxide vapour generator (Puriter) located outside the decontaminated rooms in a technical or unclassified area. The hydrogen peroxide vapour is distributed to the decontaminated areas through a separate pipework leading from the generator to the nozzles on the ceiling of each room. Return of contaminated air from the individual rooms is via return pipeline (HVAC).

Control is possible from the master control station or directly from the Puriter. The decontamination process can also be monitored from a connected mobile phone. Relative humidity and temperature are monitored at the outlet of each fumigated room and are the control variables for determining the hydrogen peroxide vapour decontamination process. The system can be supplemented with monitoring of hydrogen peroxide vapour concentrations and the data can be collected in a higher-level system.

Thanks to the integrated system, no repositioning of the hydrogen peroxide vapor generator is required, reducing manual setup time and eliminating human error.

|

Areas of application

Integrated Decontamination System Components

|

|

By equipment it is meant an isolator or a decontamination pass-through cabin.

Decontamination of the equipment using a hydrogen peroxide vapour generator (Puriter) can be carried out in two ways. The first option is to integrate the generator into the equipment, thus reducing the space occupation and providing a complete unit. The second option is to connect the generator from a technical or unclassified area. This option allows the use of one generator for multiple equipment that needs to be decontaminated. The distribution of hydrogen peroxide vapour is provided by a pipeline and the return of contaminated air is provided by the equipment to which the generator is connected.

|

Description of the Integrated Decontamination System Components

|

Preparation of the fumigation area

Transition from working operation of the HVAC system to fumigation process

Decontamination process

Ventilation of the space after fumigation

{{ msg }}

*Cliccando il pulsante di invio, autorizzo il trattamento dei dati personali