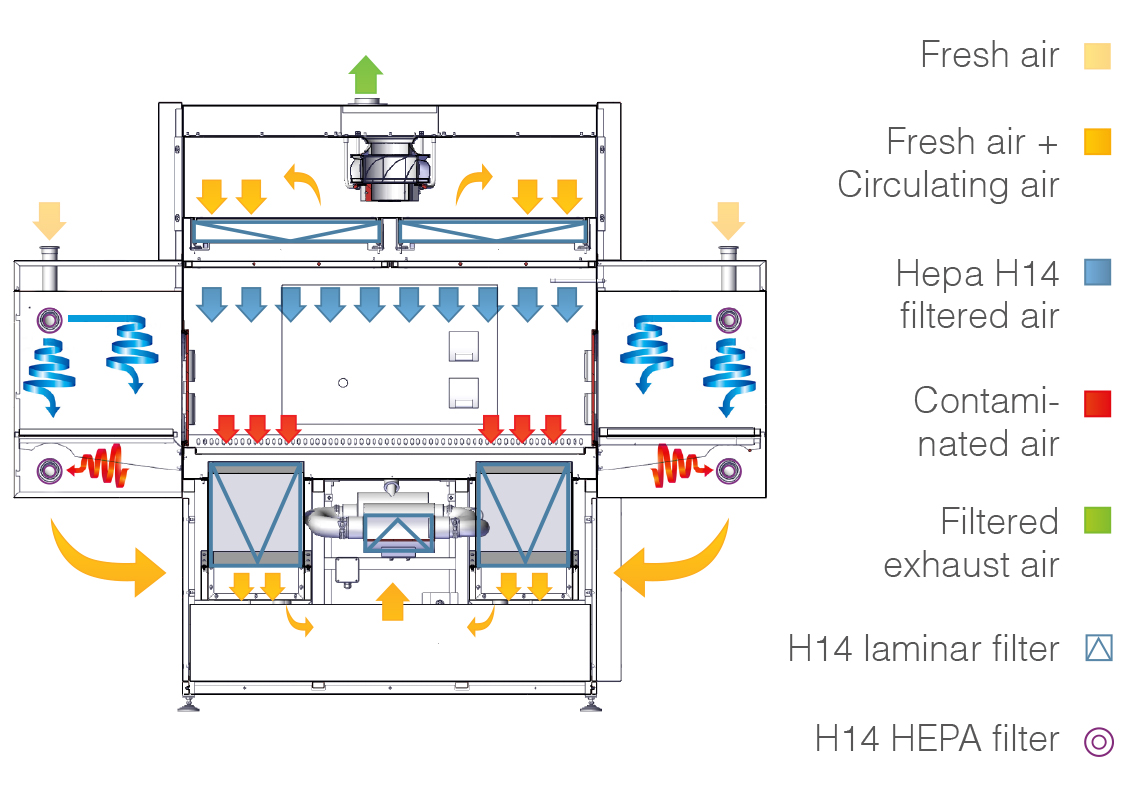

Laminar flow is used for “A” class cleanliness, when unidirectional airflow must be ensured in a vertical orientation. A laminar frame is used to direct the flow— it is comprised of a special very finely perforated fabric. The velocity of laminar flow produced by the isolator technology amounts to 0,45 m/s ±20%. HEPA filters (H14), with an efficiency of 99.995% are used to filter incoming and outgoing air. This system is often coupled with air re-circulation inside the chamber.

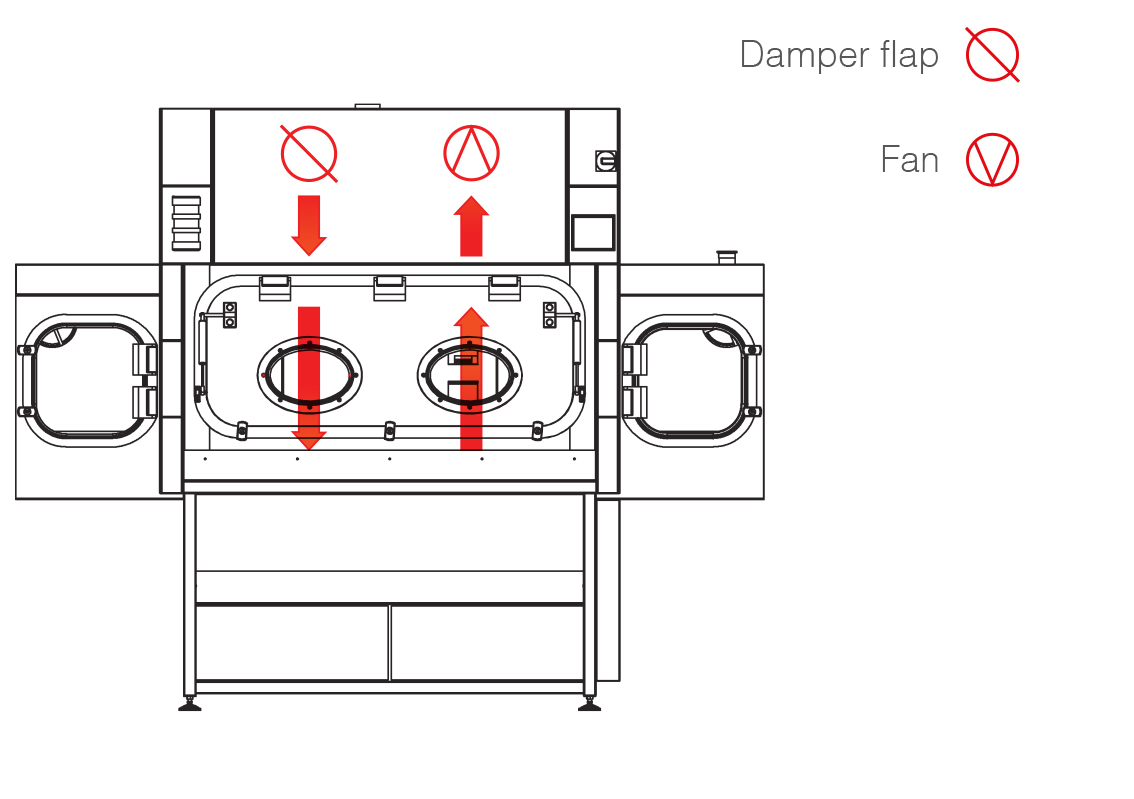

An HVAC system allows for the formation of negative pressure inside the isolator. This function is mostly used in case of isolation failure - compromised leak-proofness - and assists in protecting personnel.

Another level of protection for critical points in the process is the creation of a pressure cascade, so that the vicinity where the dangerous substance is handled is in the location with the highest negative pressure. This minimizes the risk for contamination of other chambers or the surroundings.

In order to prevent damage to the equipment caused by insufficient pressure a pneumatic valve is used for device protection. This protective function prevents the pressure from dropping even further thus saving the technology from damage.

Allows material transport to the working chamber (Airlock 1) and from the working chamber (Airlock 2).

During material transport only one of the pass-through chamber doors can remain open, thereby preventing connection of the working chamber with the surroundings.

A beacon light and an acoustic alarm provide a quick audible and visual assessment of operation and failure states for the user.

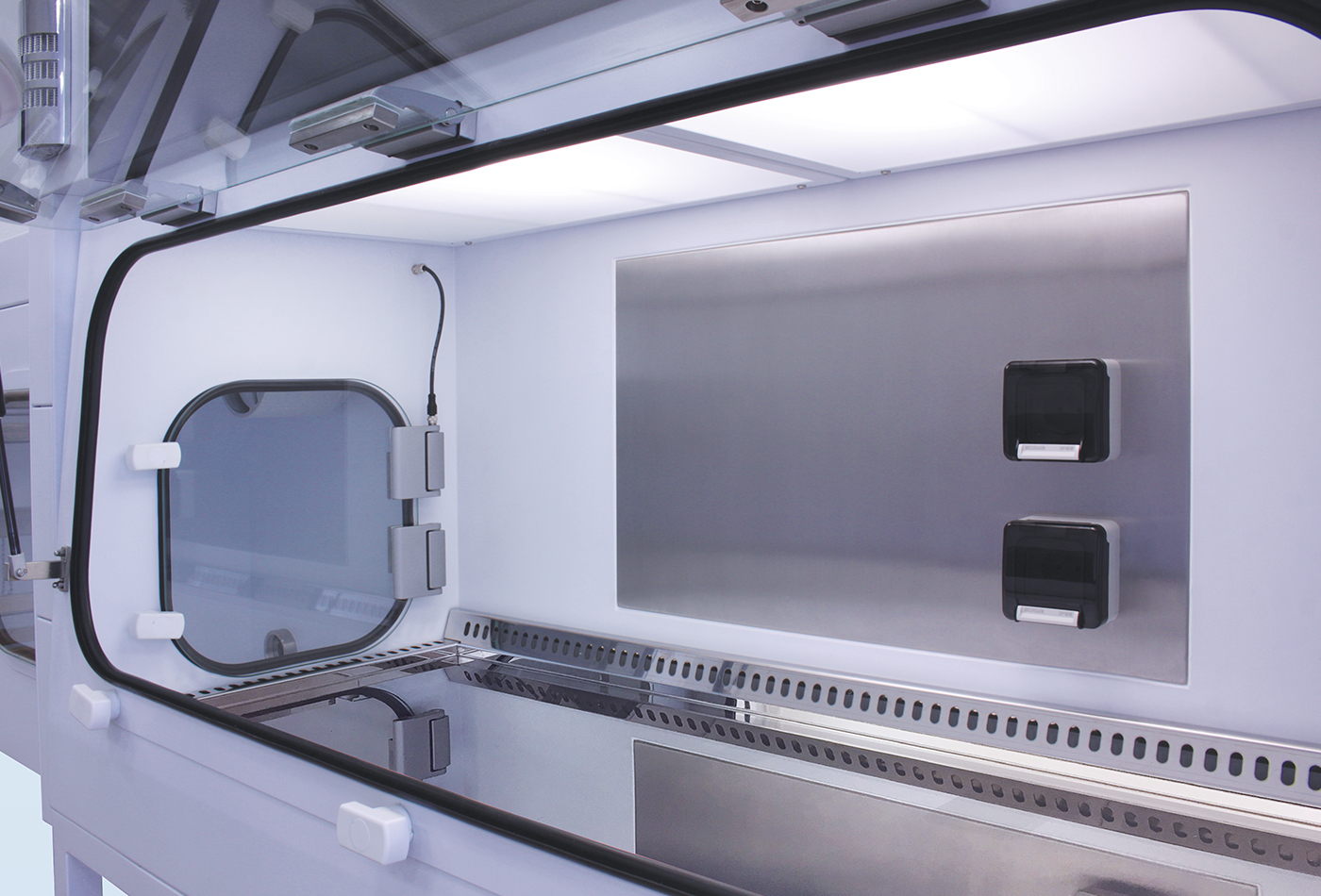

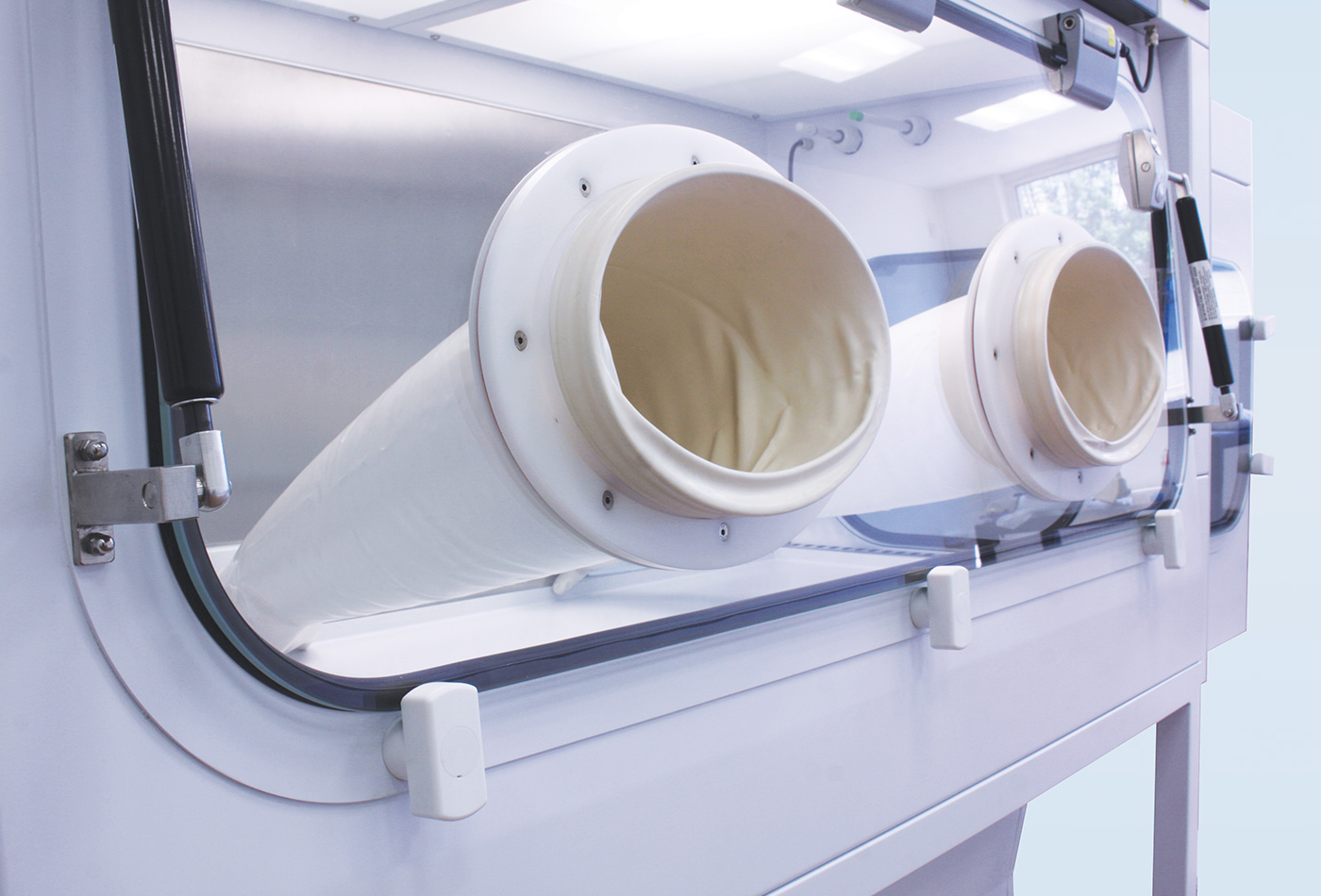

A gas spring assists with easy opening. Hinged with position control for safe closure. Installed with safety glass and fitted with flanges for sleeves. Sensors monitor safe closure of the window.

Hinges with built-in position sensors. The control system monitors the current status of the front window and produces an alarm in case two doors are opened simultaneously.

Switchboard with protection IP44.

This interchangeable rear panel allows accessories to be built in according to customer requirement. With the option to utilise a standardised design of the rear panel or a specific tailor-made design.

A laminar frame is used for orientation of airflow that contains an extra fine perforated steel sheet and special fabric.

In the interior rear wall of the main chamber SCAME sockets are placed and covered by a mechanically lockable safety latch. Our standard delivery consists of two IP66 sockets in the main chamber.

The entrance door of the pass-through cabin is equipped with a mechanical door-locking mechanism and hinges with positional control.

Set of sensors located inside the main chamber. Controlling sensor for air velocity is placed 250 mm above the air inlet. For monitoring of temperature and relative humidity iss used second sensor.

The working surface is made from highly polished AISI 316 stainless steel. For optimum airflow, air is exhausted through a perforation on the sides of the working surface.

This isolator is equipped with a Siemens Simatic electronic control system. The system is used to control, manage and regulate all operating and emergency conditions. System control is via a colour touch panel which features all control buttons and displays, process data and fault messages. The control panel is situated in the upper structure above the chambers.

The control system can transmit all operating data from the isolator to a master system where the data is archived.

The control system is also used for graphically displaying archived data and trend evaluation. This data can be transmitted to a personal computer or master system for detailed data processing.

Dimensions in mm - Biological safety cabinet class lll

| Width | 2440 |

| Height | 1950 |

| Front height | 1450 |

| Depth | 770 |

| Main chamber working plate height | 825 |

| Glove position | 1090 |

| Main chamber usable depth space | 596 |

Dimensions in mm - Main chamber

| Width | 1340 |

| Depth | 600 |

| Height | 695 |

| Main chamber total volume | 0,55 m3 |

Dimensions in mm - Airlock 1, Airlock 2

| Width | 550 |

| Depth | 460 |

| Height | 665 |

| Airlock Total volume | 0,17 m3 |

Download

Free download

| Name | Type | Availability | Size |

|---|---|---|---|

| BLOCK Technology_Company profile_EN | 11.84 MB | ||

| BLOCK Technology_Overview_EN | 2.3 MB |