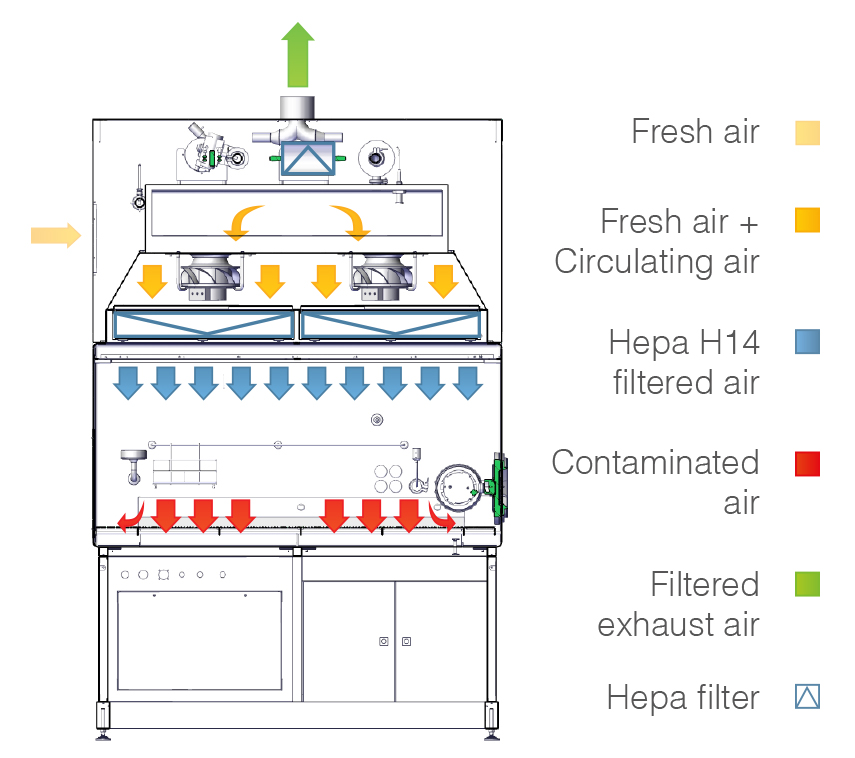

Laminar flow is used for “A” class cleanliness when unidirectional airflow must be ensured in a vertical orientation. A laminar frame is used to direct the flow— it is comprised of a special very finely perforated fabric. The velocity of laminar flow produced by the isolator technology amounts to 0,45 m/s ±20%. HEPA filters (H14), with an efficiency of 99.995% are used to filter incoming and outgoing air. This system is often coupled with air re-circulation inside the chamber.

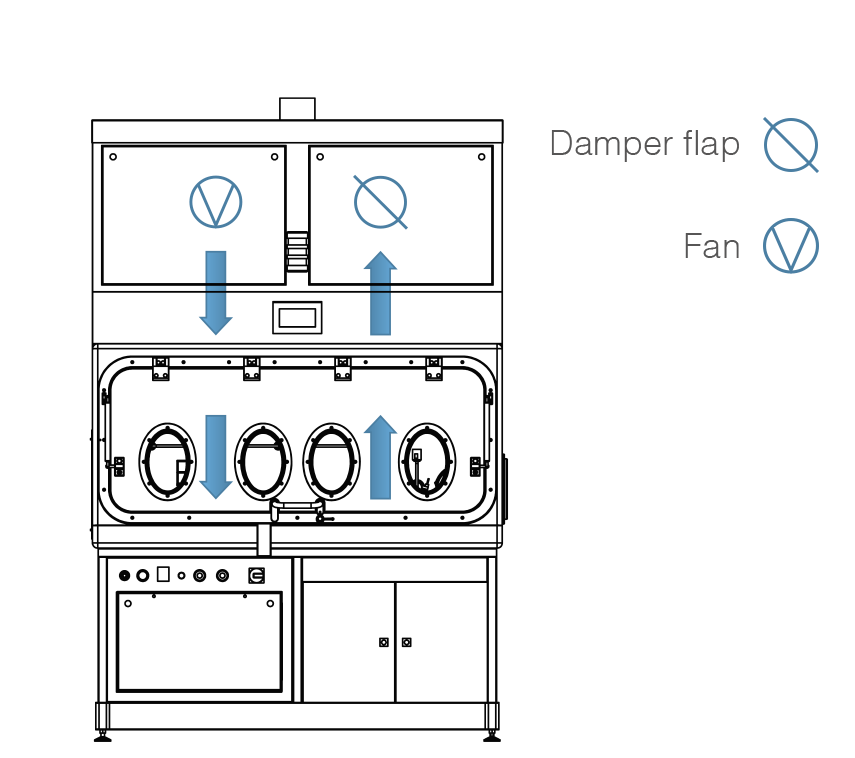

The HVAC system allows for the formation of positive pressure in the interior of the isolator. This function is mostly used in case of a failure - compromised leak-proofness - and helps protect products.

In order to prevent damage to the equipment caused by insufficient pressure a pneumatic valve is used. This protective function prevents the pressure from dropping further, protecting the technology from damage.

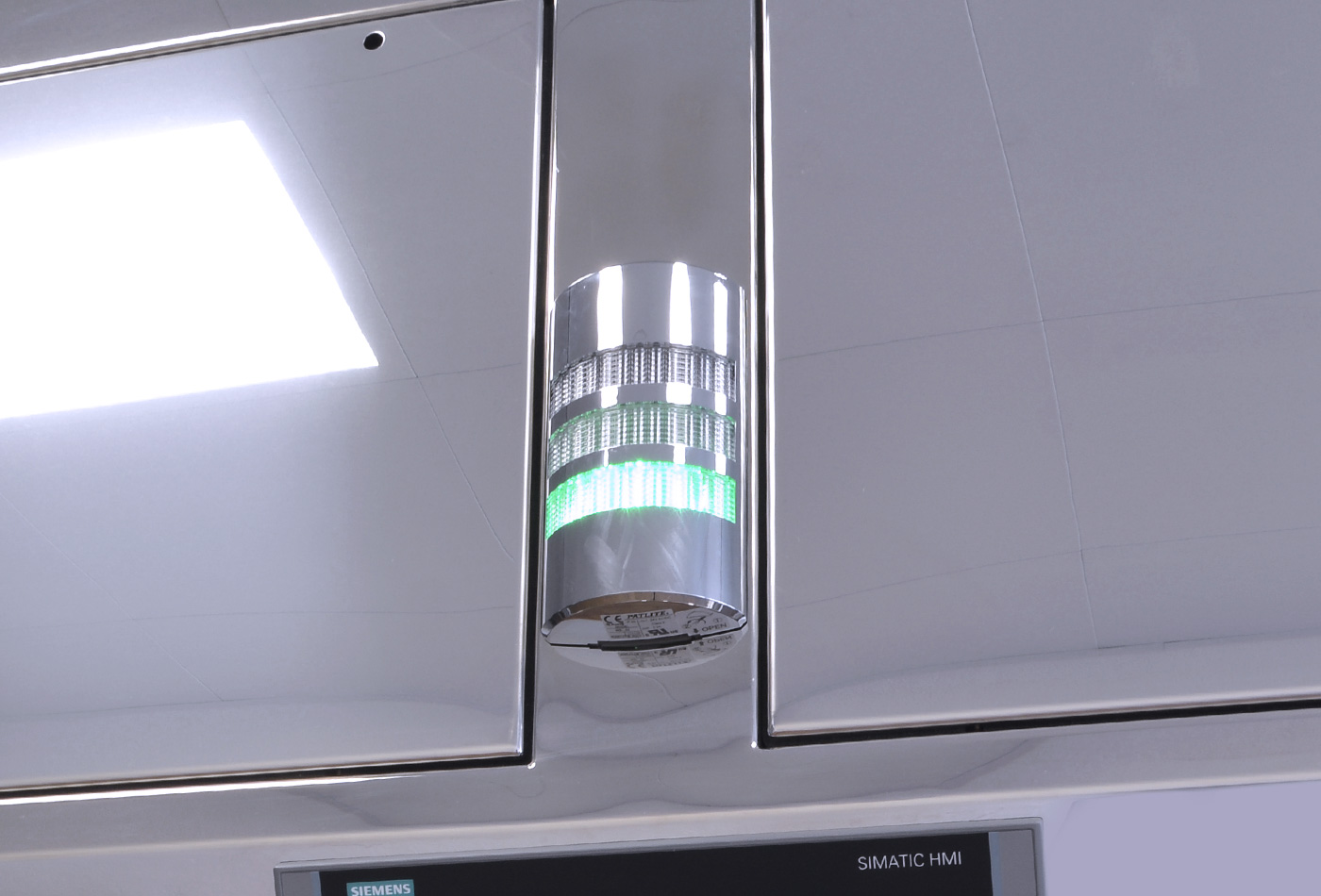

A beacon light and an acoustic alarm providing a quick audible and visual assessment of operation and failure states for the user., placed above the K1 working chamber.

Inflatable sealing safety glass fitted with sleeved flanges. Sensors for monitoring safe window closure. A gas spring is used for easy opening.

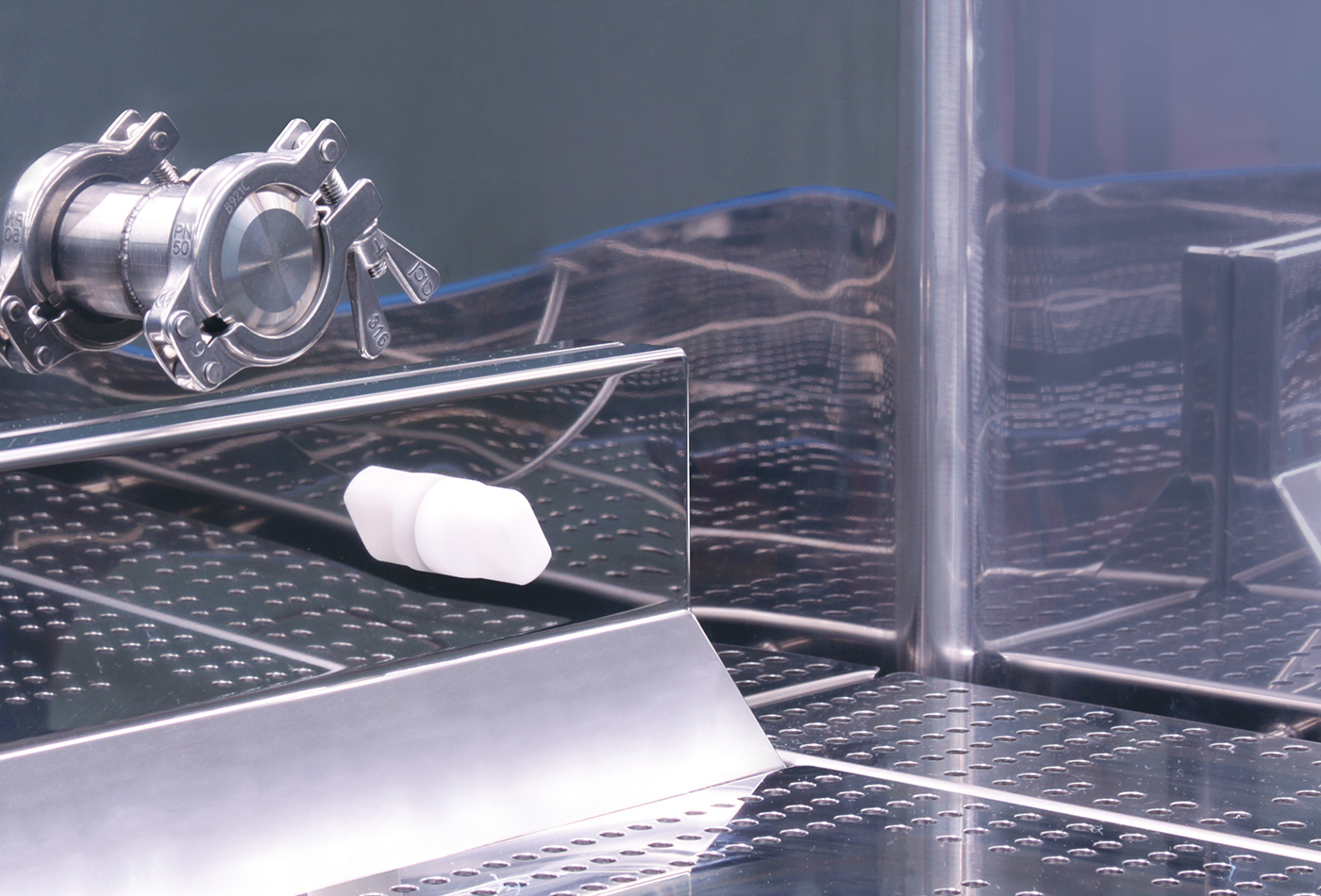

For outlet of liquid waste originating from sterility testing. Connection to a collecting tank or central waste.

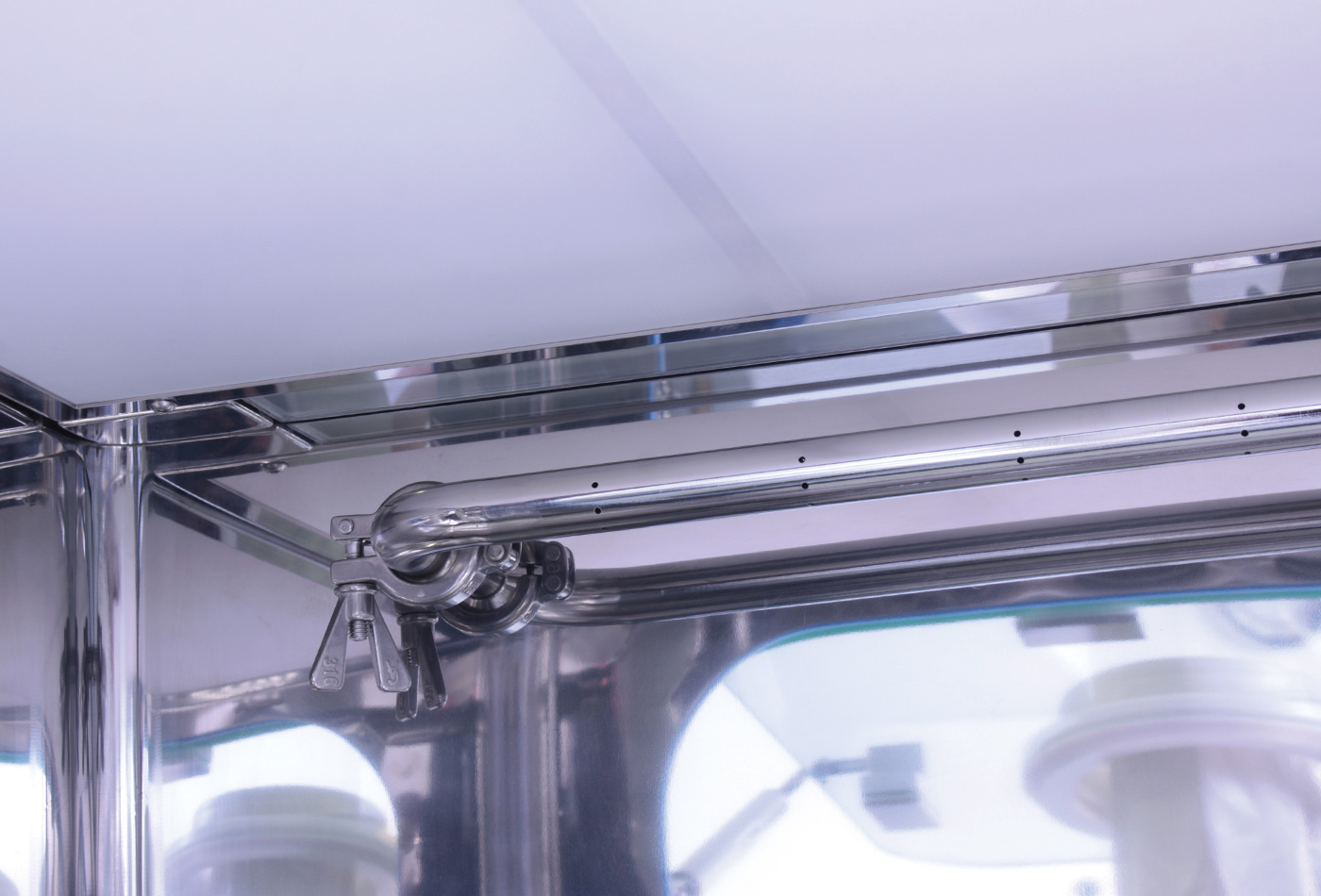

This isolator can be sterilized with hydrogen peroxide vapours. These vapours are generated by an additional external device – Puriter ( hydrogen peroxide vapour generator). Coupling clamps are located on the rear and bottom sides of the isolator.

Ready-equipped for an Airlock.

Sensors for monitoring safe window closure.

The site for the RTP is placed on the chamber´s right wall. Option to integrate an RTP alpha port and beta container for sterile transfer of materials.

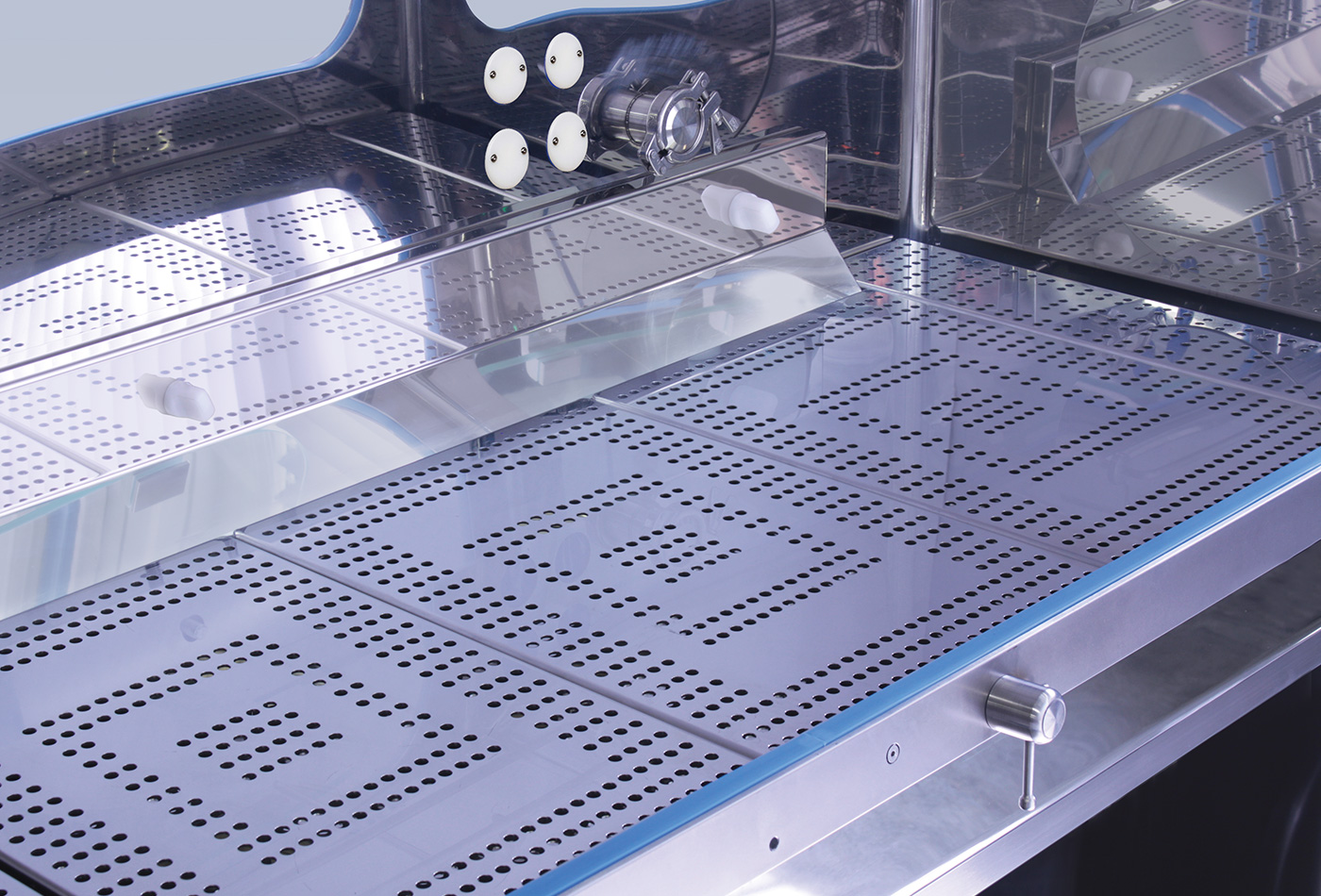

The worktop is equipped with 6 perforated grates. The grates can be fitted with a device for sterility testing.

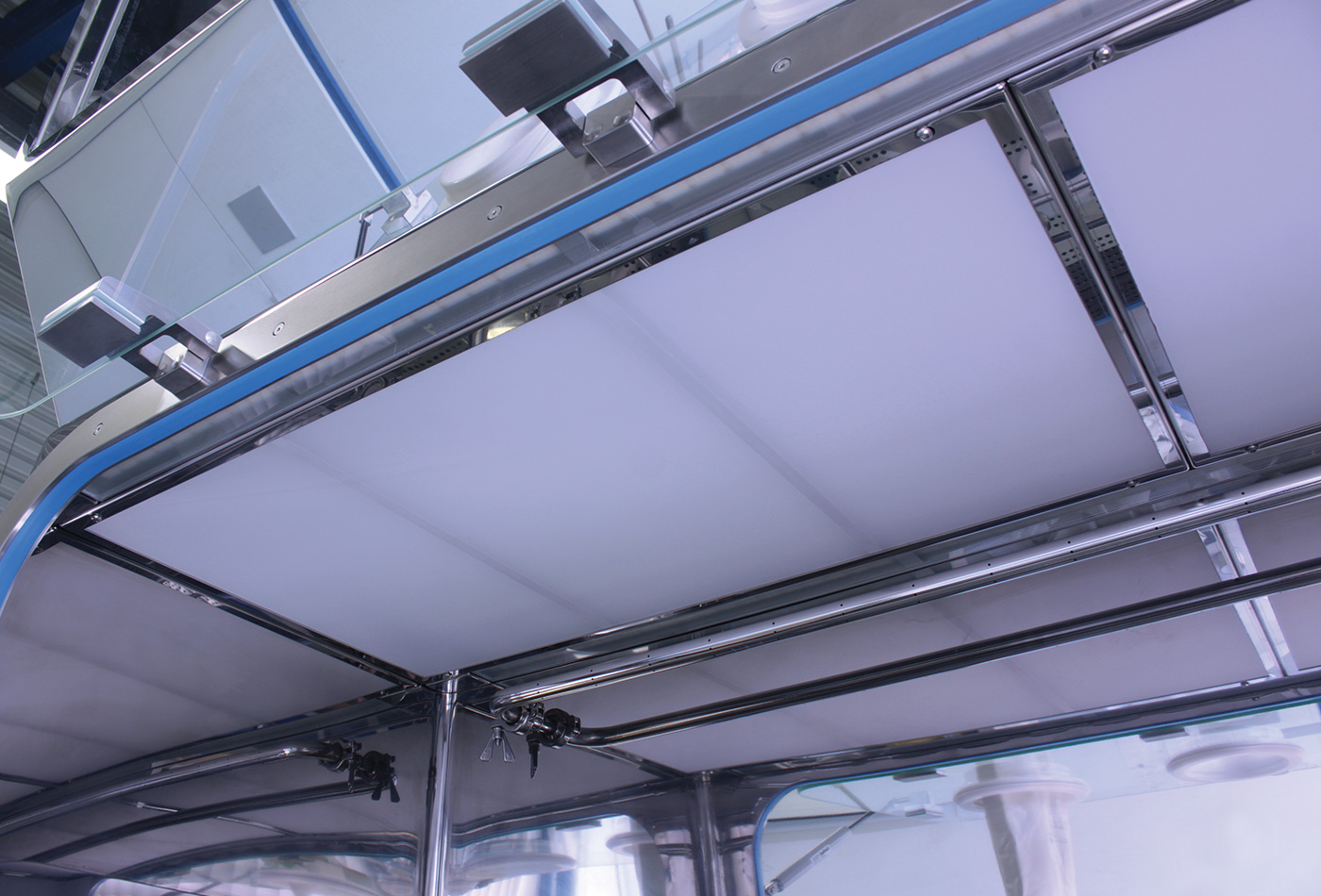

The chamber ceiling is fitted with a laminar frame for producing laminar flow, and includes built-in LED lights. Inlet HEPA filters are situated above the laminar frame.

This isolator can be sterilized using hydrogen peroxide vapours. A uniform distribution of vapour is achieved using a perforated pipe installed through the whole length of the chamber.

Rounded corners and highly polished surfaces allow for easy cleaning of the chamber. The chambers are seal-welded which guarantees their leak tightness.

This isolator control system is operated with a Siemens color touch screen. The Simatic control system from Siemens together with a foot operated switch creates an intuitive and user-friendly experience. The screen displays the actual parameters of the environment and monitors emergency statuses. The system includes remote access for customer service support. As required, it is possible to implement connection to an additional device for production data storage and export.

Dimensions in mm - Sterility test isolator

| Width | 1800 |

| Height | 2730 |

| Front height | 1750 |

| Depth | 1090 |

| Working plate height | 940 |

| Glowes position* | 1230* |

| Usable space depth | 650 |

* Adaptable on request

Dimensions in mm - working chamber K1

| Width | 1800 |

| Depth | 650 |

| Height | 900 |

| K1 chamber Total volume | 1,05 m3 |

Dimensions in mm - pass-through chamber K2

| Width | 550 |

| Depth | 650 |

| Height | 900 |

| K2 chamber Total volume | 0,3 m3 |

Download

Free download

| Name | Type | Availability | Size |

|---|---|---|---|

| Sterility Test Isolator_Aseptic Isolator_EN_2021 | 6.69 MB | ||

| BLOCK Technology_Company profile_EN | 11.84 MB | ||

| BLOCK Technology_Overview_EN | 2.3 MB |